About us

At NTT, we control the full production cycle — every component is made in-house.

This gives us the power to maintain top-level quality and respond quickly to new market demands, custom designs and brand innovations.

Discover what sets us apart:

PLYWOOD

HANDLES

BLADES

RUBBER

Production

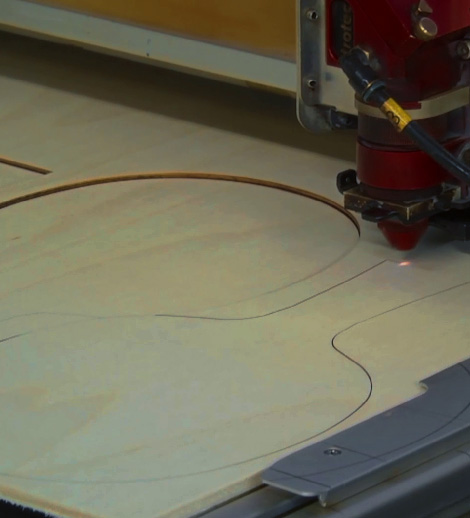

PLYWOOD

- Plywood for blades and boards of dyed veneer for handles are made at site.The maximum size of dyed plywood is 560 x 560 mm, and the maximum thickness is 50 mm.

- The maximum size of the plywood made of natural aspen anbirch veneer is 1100 x 1100 mm, and the thickness is up to 20 mm.

Production

HANDLES

- NTT produces handles both of massive wood (birch, aspen and ash) and also natural dyed veneer glued in beautiful patterns.

- We dye the veneer ourselves and glue the plywood to make complicated designs that is why we can fulfill your order according to your own designs and shapes, or work out and offer our own collections in a very short time.

Production

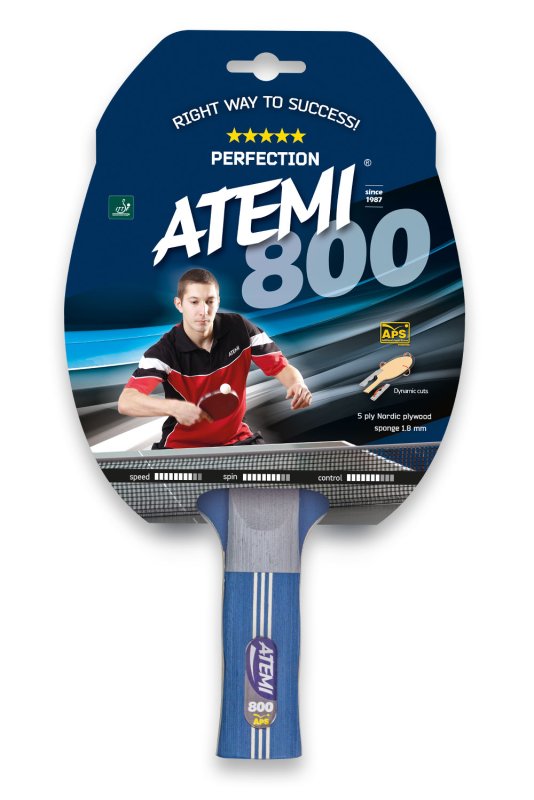

BLADES

- Now, we have developed a wide range of professional blades. On the level of classical variants ALL and OFF we also offer you our models – NTT blades elaborated by our Rsearch & Development department

- Our modern equipment, the use of exotic and nordic kinds of wood as well as new techniques in production enable us to produce high quality blades with stable characteristics. We hope you will recognize their value.

Production

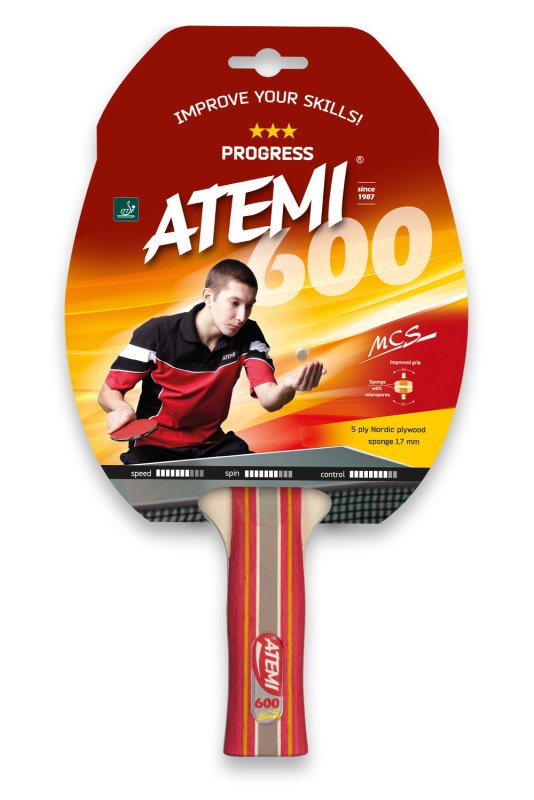

RUBBER

- The rubber covering is one of the most important components, which play a decisive role in the playing characteristics of a racket.

- Modern technology, unique equipment and excellent formulae of rubber and sponge enable us to produce high quality rubber coverings from natural caoutchouc and chemical elements, which make our rubber bright, lucid and very grippy.

- All possible combinations of rubber and sponge recipes give a vide range of qualities, which satisfy the players of any level: from the very beginners to professionals participating in international championships.